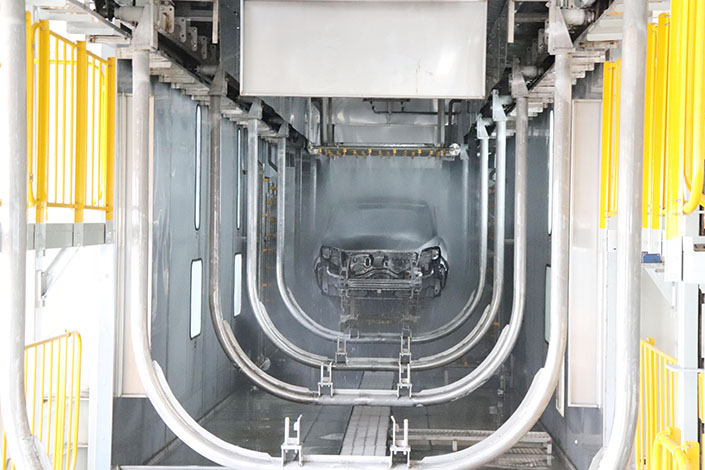

Txau hom pretreatment ntau lawm kab

Txheej pretreatment muaj xws li degreasing (degreasing), xeb tshem tawm, phosphating peb qhov chaw.Phosphating yog lub hauv paus txuas, degreasing thiab xeb tshem tawm yog cov txheej txheem kev npaj ua ntej phosphating, yog li hauv kev xyaum ntau lawm, peb yuav tsum tsis tsuas yog siv phosphating ua haujlwm, tab sis kuj pib los ntawm cov kev xav tau ntawm phosphating zoo, ua haujlwm zoo ntxiv rau. roj thiab xeb tshem tawm, tshwj xeeb tshaj yog them nyiaj rau kev sib nrig sib cuam tshuam ntawm lawv.

Degreasing kev puas tsuaj

Nrog rau kev txhim kho kev lag luam, kev tiv thaiv ib puag ncig thiab kev txhim kho kev ua haujlwm tau dhau los ua kev txhawj xeeb ntawm tib neeg.Yog li ntawd, qhov xav tau ntawm kev tiv thaiv ib puag ncig yuav tsum raug coj mus rau hauv tus account thaum xaiv cov neeg sawv cev.Yog li ntawd, kev xaiv cov roj tshem tawm tus neeg sawv cev yuav tsum tau npaj yooj yim, deconfouling muaj peev xwm muaj zog, tsis muaj sodium hydroxide, silicate, OP emulsifier thiab lwm yam khoom uas nyuaj rau ntxuav ntawm chav tsev kub, yooj yim ntxuav ntawm chav tsev kub, tsis muaj tshuaj lom. tshuaj, tsis tsim cov pa phem, ua haujlwm zoo.Kev xaiv cov xeb tshem tawm yuav tsum tau suav nrog cov neeg txhawb nqa, cov tshuaj tiv thaiv corrosion thiab inhibitors, tuaj yeem txhim kho qhov ceev ntawm xeb tshem tawm, tiv thaiv lub workpiece los ntawm over-corrosion thiab hydrogen embrittlement, tuaj yeem inhibit acid pos huab.Nws yog tshwj xeeb tshaj yog tsim nyog rau cov kua qaub pos inhibiting, tshwm sim nyob rau hauv tus txheej txheem ntawm pickling acid pos huab, corrosion ntawm cov khoom thiab cov nroj tsuag, tsis tsuas pollute ib puag ncig, thiab yuav ua rau cov hniav lwj, hniav conjunctival redness, kua muag, mob, qhuav caj pas, hnoos thiab lwm yam tsos mob. , yog li zoo inhibit acid pos huab, tsis tsuas yog xav tau kev tiv thaiv ib puag ncig, lossis kev noj qab haus huv rau cov neeg ua haujlwm xav tau.

Kev ntxuav dej

Ntxuav tom qab tshem tawm cov roj thiab xeb, txawm hais tias nws belongs rau cov txheej txheem pab ua ntej pleev xim, nws kuj yuav tsum tau ua kom txaus txaus.Tom qab cov roj tshem tawm thiab xeb tshem tawm, qhov saum npoo ntawm lub workpiece yog ib qho yooj yim rau ua raws li qee qhov tsis-ionic surfactants thiab CL-.Yog tias cov khoom seem no tsis raug ntxuav kom huv si, lawv tuaj yeem ua rau phosphating film thinning, linear defects, thiab txawm tias phosphating.Yog li ntawd, txhawm rau txhim kho qhov zoo ntawm kev ntxuav dej tom qab tshem tawm cov roj thiab xeb, nws yog ib qho tsim nyog yuav tsum tau mus los ntawm ntau cov rinses, ob lub rinses, lub sij hawm 1-2min, thiab nquag hloov dej kom ntseeg tau tias PH tus nqi ntawm cov dej nyob nruab nrab ntawm 5-7. .

Phosphating

Lub thiaj li hu ua phosphating, hais txog cov hlau workpiece tom qab uas muaj cov tshuaj dihydrogen phosphate acid, tshuaj cov tshuaj tiv thaiv thiab nyob rau hauv nws nto los tsim ib txheej ntawm ruaj khov insoluble phosphate zaj duab xis, zaj duab xis yog hu ua phosphating zaj duab xis.Lub hom phiaj tseem ceeb ntawm phosphating zaj duab xis yog ua kom cov adhesion ntawm txheej thiab txhim kho corrosion kuj ntawm txheej.Muaj ntau txoj hauv kev ntawm phosphating, raws li qhov kub thiab txias ntawm phosphating, tuaj yeem muab faib ua phosphating kub (90-98 ℃), nruab nrab kub phosphating (60-75 ℃), tsis kub phosphating (35-55 ℃) thiab kub ib txwm phosphating.

Passivation

Kev siv thev naus laus zis ntawm phosphating zaj duab xis yog dav siv hauv North America thiab European lub teb chaws.Lub tshuab passivation yog raws li cov yam ntxwv ntawm phosphating zaj duab xis nws tus kheej.phosphating zaj duab xis yog nyias, feem ntau nyob rau hauv 1-4G / m2, qhov siab tshaj plaws yog tsis ntau tshaj 10g / m2, qhov dawb pore cheeb tsam yog loj, thiab corrosion kuj ntawm cov zaj duab xis nws tus kheej yog txwv.Qee qhov txawm tias nyob rau hauv cov txheej txheem ziab ntawm cov xeb sai sai, tom qab phosphating ib qho kev kho mob kaw, tuaj yeem ua phosphating zaj duab xis pore raug hlau oxidation, los yog tsim cov txheej txheem passivation, phosphating zaj duab xis tuaj yeem ua si sau, oxidation, ua phosphating zaj duab xis ruaj khov nyob rau hauv huab cua.

Qhuav ntawm phosphating zaj duab xis

Kev ziab cov phosphating zaj duab xis tuaj yeem ua ob lub luag haujlwm, ntawm ib sab, nws yog los npaj rau cov txheej txheem tom ntej kom tshem tawm cov dej ntawm cov phosphating zaj duab xis, ntawm qhov tod tes, nws yog txhawm rau txhim kho corrosion kuj ntawm zaj duab xis. tom qab txheej.

Txhawm rau tsim cov txheej txheem pretreatment kab, cov txheej txheem tsim yuav tsum ua kom tiav ua ntej tsim, tsim khoom thiab teeb tsa cov khoom siv tsis yog txheej txheem.Yog li ntawd, tus txheej txheem tsim yog lub hauv paus ntawm cov kab ntau lawm, thiab txoj kev raug thiab tsim nyog yuav muaj kev cuam tshuam zoo rau kev tsim khoom thiab cov khoom zoo.

Siv rau txhua yam ntawm workpiece painting, lwm yam qauv yuav customized.